A. DESCRIPTION

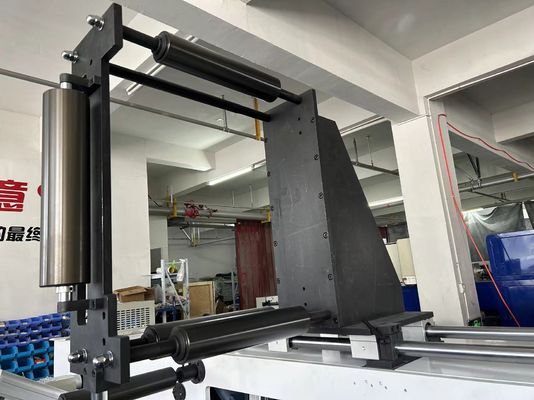

1. unwinding unit

• automatic loading/unloading by cylinder

• auto stop when paper roll is finished

2. Auto web guiding (dexing)

• with pneumatic splicing table

• the paper guide roller adopts high hardness anodized

• ultrasonic sensor, system can correct when paper goes skewing.

• precision:±0.12mm

3. In/Out-feeding system

• rubber rollers for feeding

• servo motor

4. Printing unit 8 units

• drive system: Mechanical type

• pneumatic for opening and closing anilox roller and printing roller

• ceramic anilox roller. 1 pcs per printing unit, customized

• printing roller. 1 pcs per printing unit, customized ( Steel material less than 130T, aluminum material more than 131T )

• stainless steel ink box, single doctor blade.

• adopts petal structure, the pressure is stable, and the printing cylinder can be changed fast

• printing plate automatically cleaning function: printing roller keeps rotating for 1.5s to pass the ink to paper when machine is stopped each time, it can make plate clean.

• anilox roller rotate itself function: anilox roller will rotate itself when machine is stopped, to avoid ink dry on face of anilox roller.

• gear mode:cp1/8, material 20CrMnTi, long working life.

5. Drying system

6. Video camera

7. turn bar

8. Central rewinding unit

• stop when paper is cut off

9. Auto stopping function

• pre-set printing meter, and machine will stop automatically

10. Touch screen

11. Mark sensor auto registration system, to save material

B. Technical parameter

1 Unwinding/rewinding diameter: 600mm

2 Printing repeat: 181mm-600mm

3 Max width: 350mm

4 Max printing width: 340mm

5 Material thickness: 30-300gsm paper, pet 12-60um,opp 18-60um

6 Gear pitch: 1/8inch (3.175mm)

7 Printing plate thickness: 1.7mm

8 Double glue tap thickness: 0.38mm

9 Printing precision: ±0.1mm

10 Power supply: 380V 3PH 50Hz

11 Machine speed: 0-180m/min

12 Air compressor: 100PSI (0.6Mpa)

13 Tension area: 5-100kg

14 Rewinding motor: 4KW

15 Printing servo motor: 1.8KW

16 traction servo motor 2.9kw

C. Configuration

| Name |

Model |

Brand |

| Motion controller |

|

Innovance |

| Main touch screen |

15” |

INNOVANCE |

| servo motor/drive |

1.8KW |

Innovance |

| Unwinding tension controller |

|

ZXTEC |

| Rewind motor |

4 Kw |

Shanghai |

| Servo driver |

1.8Kw |

INNOVANCE |

| PLC |

|

INNOVANCE |

| air cylinder |

|

AIRTEC |

| Web guiding |

|

KESAI |

| Video camera |

Observer 4000M |

KESAI |

| Switch power supply |

|

Meanwell - Taiwan |

| Pneumatic components |

|

Airtec |

| Belt |

|

Saini - Ningbo |

| Cameric anilox roller |

|

Shanghai brand |

| All low-tension electrical |

|

CHINT / Schneider |

| Fan |

|

Xuchi - Wenzhou |

| Lubricating motor |

|

Taiwan |

| Electrical proportional valve |

|

AIRTEC |

| Linear guides |

|

Weiyi - Lishui |

پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!  پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!